OMS Sr.l. - Filling & Capping Systems > Filling Machine

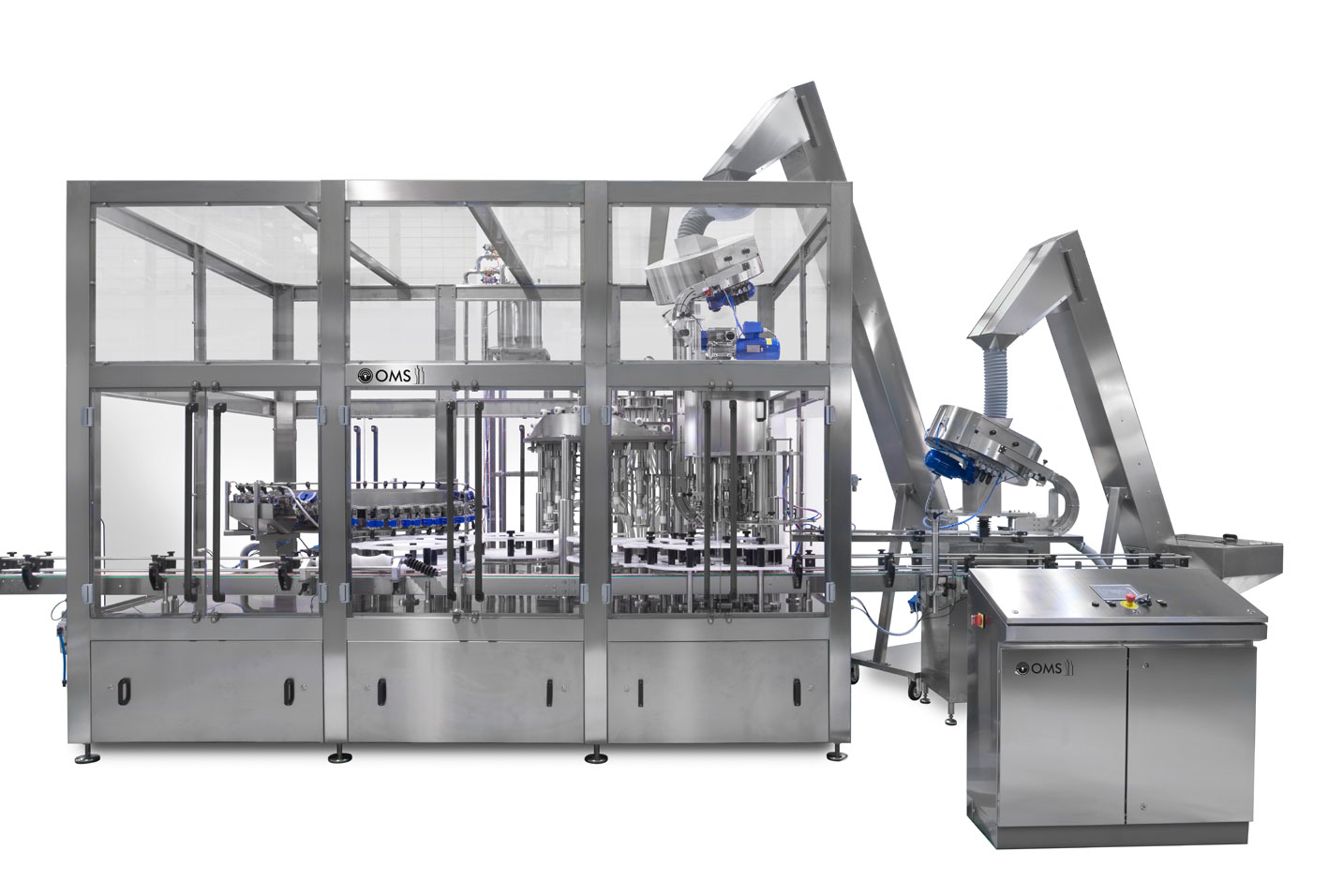

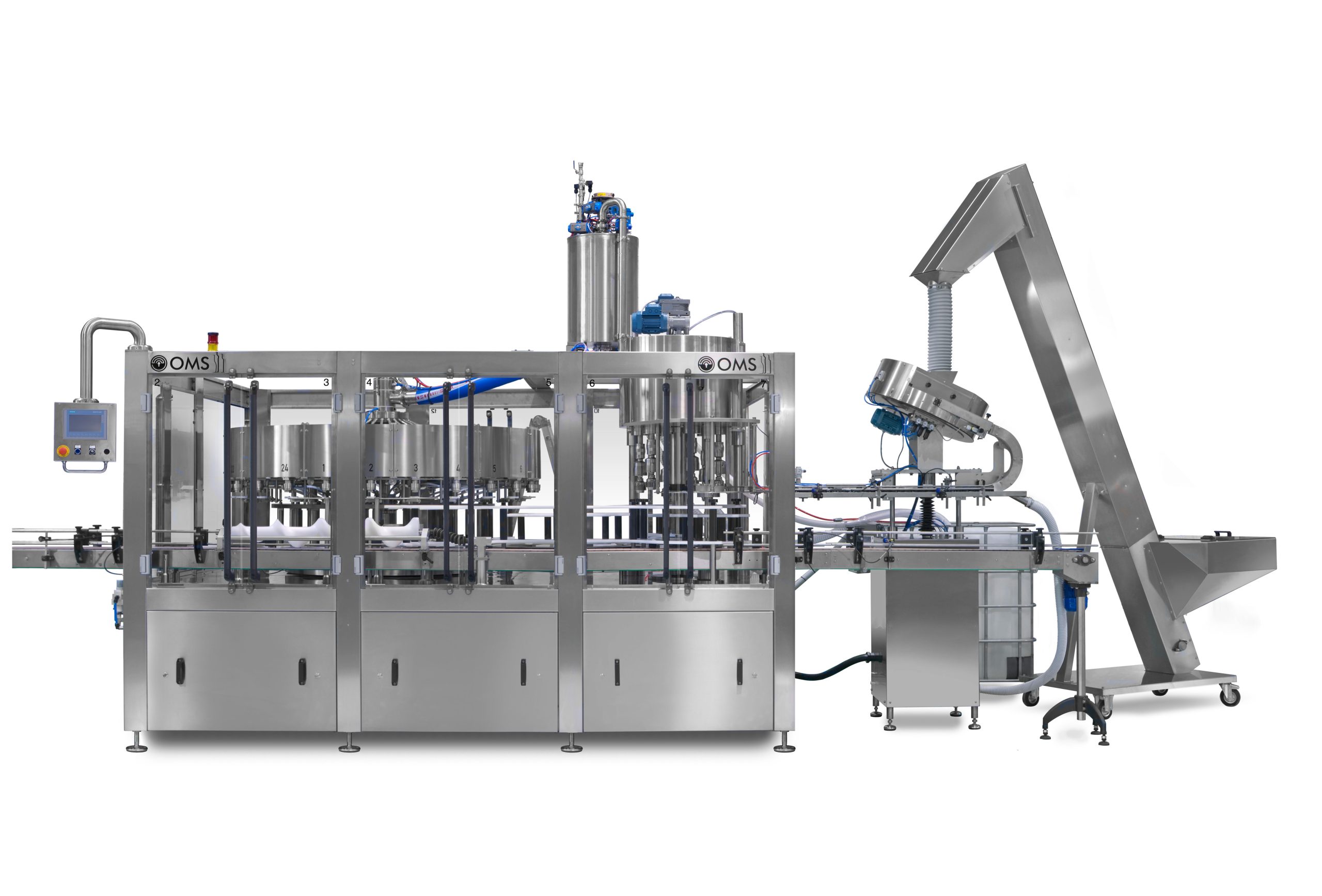

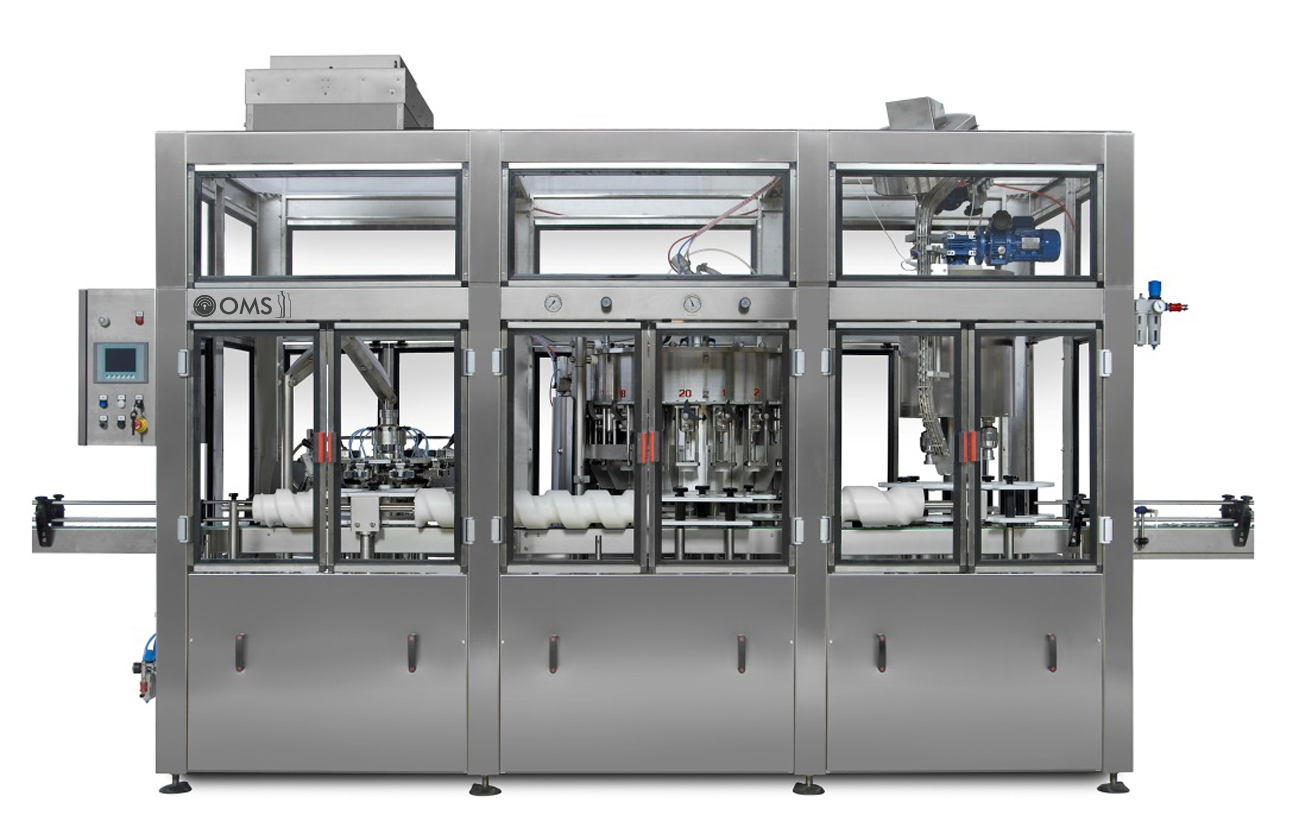

The automatic filling machines are designed for filling bottles and containers in

GLASS, PET, PE, HDPE and METAL with any type of liquid.

The filling system, which changes according to the liquid to be bottled, can be gravity / pressure (RVD models), volumetric (RVP models), counter pressure (RIS models) or electronic flowmeters (RFM MAG and RFM MAS models). All machines are available in both rotary and linear versions.

Specifically, gravity / pressure filling is suitable for bottling low and medium density products such as water, still drinks, juices, liqueurs and spirits. Volumetric filling is recommended for bottling dense and viscous products such as oils, syrups, detergents, household and personal care products. Electronic fillers with flow meters are suitable for those types of liquids that need special and high precision treatments. The isobaric fillers for filling carbonated liquids.

Designed for productions from 1.000 B/H to 25.000 bph, the OMS fillers can be independent or integrated into more complex systems as monobloc (filler/capper) or multi-block (rinser/filler/capper).

Upon request, Neck-Handling, Hot-Fill systems can be supplied with product recycling in the customer’s pasteurizer, C.I.P and S.I.P. predisposition, laminar flow systems and with ATEX certifications.